Excavator Control Patterns

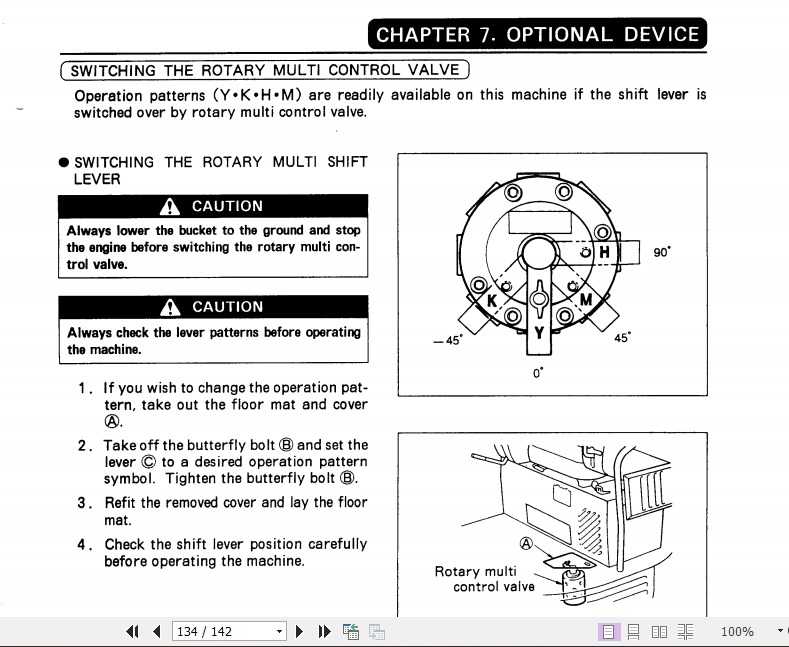

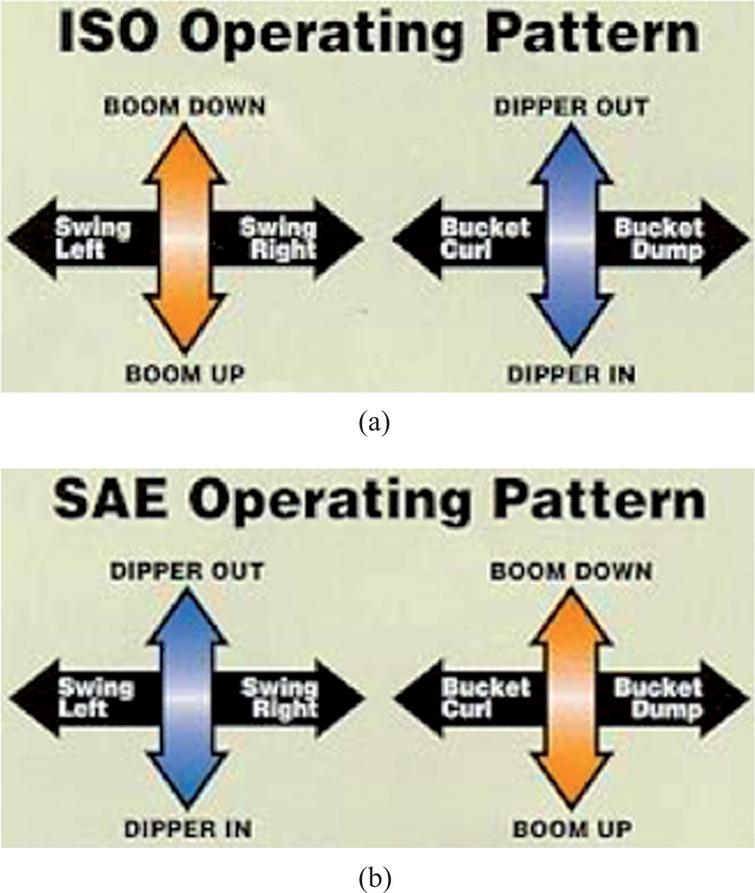

Excavator Control Patterns - Web the most commonly used control pattern throughout the world is the iso controls. How does the sae control pattern work? I don't have much experience with excavators but an opportunity has come up to run one on a fairly frequent basis. The difference between the two is that in iso, the left hand controls the swing and boom and the right hand controls the stick and bucket motions. These are the two standard control patterns for excavators. Turn the lever to change the pattern. Your screen will detail the saved functions for all buttons and switches on your joysticks. They're known as iso controls or sae controls. In this guide, we’ll walk you through the process of switching excavator controls from iso to sae, ensuring that you can seamlessly adapt to different operational requirements. Sae controls are commonly found in construction machinery in the us. Effects of machine instability feedback on safety during digging operation in teleoperated excavators. This post explains the difference between the two and shares essential excavator safety tips. Web before we start going through the excavator controls, you should know that there's really two different control patterns that you'll find on machines. Your screen will detail the saved functions for all buttons and switches on your joysticks. Web the most commonly used control pattern throughout the world is the iso controls. Unscrew the bolt holding the lever in place. Refer to your machine’s operator manual to find the exact location and instructions for your specific model. Web excavator control pattern (iso standard). Web one crucial aspect that operators often encounter is the choice between iso and sae control patterns. There are two different types of control patterns for excavator: Web we will go over five important aspects to operating an excavator, including controls, driving/operating, digging, backfilling and parking. These are the controls that are standard to the society of automotive engineering for vehicle construction. Effects of machine instability feedback on safety during digging operation in teleoperated excavators. Refer to your machine’s operator manual to find the exact location and. Web we will go over five important aspects to operating an excavator, including controls, driving/operating, digging, backfilling and parking. I'm looking for some advice on which control patterns you favor when operating a mini excavator. Can i change the control pattern in my machine? These are the two standard control patterns for excavators. In the iso control pattern, the left. These are the two standard control patterns for excavators. For many operators today the thought of using the traditional backhoe cross style control layout is a daunting prospect, but for those of us of a certain age, we grew up with them and as. I'm looking for some advice on which control patterns you favor when operating a mini excavator.. Left joystick, right joystick, lever pattern, restore to factory setting and current configuration. Web you will see five options: Quick & easy iso pattern. In the united states, sae controls are the more popular control pattern. In the iso control pattern, the left hand joystick controls swing (left & right) and the stick boom (away & close), and the right. Web it’s important to know which joystick patterns control the boom, bucket, dipper, and swing when operating an excavator. How does the sae control pattern work? In this guide, we’ll walk you through the process of switching excavator controls from iso to sae, ensuring that you can seamlessly adapt to different operational requirements. There are two different types of control. First, check your current configurations. There are two different types of control patterns for excavator: Can i change the control pattern in my machine? I don't have much experience with excavators but an opportunity has come up to run one on a fairly frequent basis. The difference between the two is that in iso, the left hand controls the swing. There are two different types of control patterns for excavator: How does the sae control pattern work? There are two control patterns. Web we show you how easy kubota makes it to change the controls on your excavator so all operators can run an excavator on the pattern they are familiar with. There are two different operator control patterns, iso. The difference between the two is that in iso, the left hand controls the swing and boom and the right hand controls the stick and bucket motions. Web to change the control pattern on your bobcat excavator, first locate the control pattern selector valve. The main controls of an excavator are usually governed by international standards that are responsible for. Testing the new control pattern. Web one crucial aspect that operators often encounter is the choice between iso and sae control patterns. The difference between the two is that in iso, the left hand controls the swing and boom and the right hand controls the stick and bucket motions. Web the two most common control patterns for excavators are the. Effects of machine instability feedback on safety during digging operation in teleoperated excavators. Web one crucial aspect that operators often encounter is the choice between iso and sae control patterns. Web since 2011, some new models of excavators come standard with sae controls and you can easily switch to another pattern if you want. In the iso pattern, the left. Web to change the control pattern on your bobcat excavator, first locate the control pattern selector valve. First, check your current configurations. Sae controls are commonly found in construction machinery in the us. Web to change the excavator control pattern on any john deere rental equipment, follow these steps: Determine if the machine is in an iso or sae control pattern. There are two different operator control patterns, iso and sae. These are the controls that are standard to the society of automotive engineering for vehicle construction. Quick & easy iso pattern. This post explains the difference between the two and shares essential excavator safety tips. For many operators today the thought of using the traditional backhoe cross style control layout is a daunting prospect, but for those of us of a certain age, we grew up with them and as. Web the two most common control patterns for excavators are the iso (sae) and the bhl ( john deere) patterns. Basic safety tips on operating an excavator. Web it’s important to know which joystick patterns control the boom, bucket, dipper, and swing when operating an excavator. Unlock the box with the key. This valve is typically found in the cab near the operator’s seat or under the floor panel. It provides a clear and comprehensive guide for understanding the different controls and their functions, allowing operators to operate the machine efficiently and safely.Understanding the John Deere Excavator Control Pattern Diagram A

How to Use Excavator Controls (Joystick Patterns & Operation Explained

Howtochangecontrolpatternonkobelcoexcavator natthrozan

Bobcat Excavator Controls Diagram

43 backhoe controls diagram

Cat 225B LC Excavator Q&A on Controls, Patterns & Diagrams

How To Change The Control Pattern On A Bobcat Excavator

Excavator control pattern (ISO standard). Download Scientific Diagram

Cat Excavator Control Pattern Diagram Wiring Site Resource

5 Controls To Master Excavator Operation WHC Hire Services

How Does The Sae Control Pattern Work?

Web One Crucial Aspect That Operators Often Encounter Is The Choice Between Iso And Sae Control Patterns.

The Main Controls Of An Excavator Are Usually Governed By International Standards That Are Responsible For Normalizing The Actions Of The Equipment Concerning Levers Or Controls Within The Operating Cabin Regardless Of Their Brand.

Your Screen Will Detail The Saved Functions For All Buttons And Switches On Your Joysticks.

Related Post: